Flour Milling and Food Sustainability: Zero Waste Initiatives

99 exchange login password, laser 247 sign up, yolo 247: Flour milling is a vital process in the food industry that involves grinding grains into flour to produce various food products such as bread, pasta, and pastries. However, this process also generates a significant amount of waste, which can have negative environmental impacts if not managed properly. In recent years, there has been a growing interest in zero waste initiatives within the food industry, including flour milling, to promote sustainability and reduce waste.

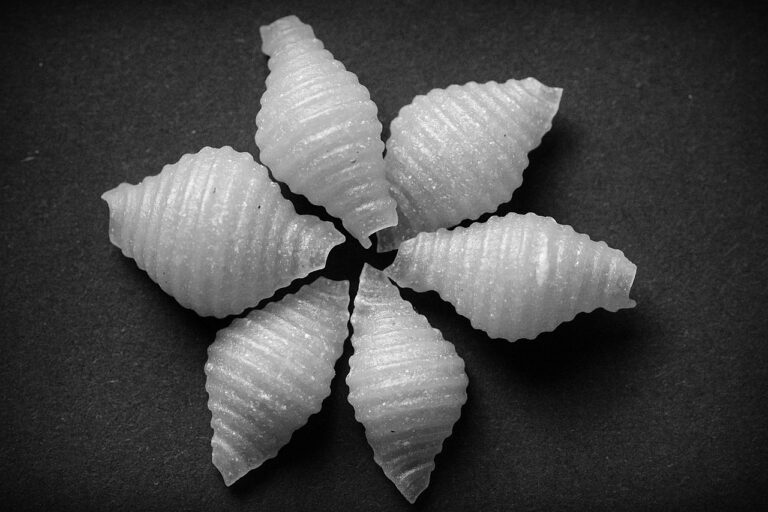

One of the key challenges in flour milling is the generation of byproducts such as bran, germ, and shorts, which are often discarded or used as animal feed. These byproducts contain valuable nutrients and fibers that can be utilized in various ways to reduce waste and promote sustainability. By implementing zero waste initiatives in flour milling, companies can find innovative ways to repurpose these byproducts and minimize their environmental footprint.

One approach to reducing waste in flour milling is through the development of new products using milling byproducts. For example, bran can be used as a healthy ingredient in baking recipes, while germ can be processed into oil for cooking or skincare products. By finding new uses for these byproducts, companies can not only reduce waste but also create additional revenue streams and appeal to environmentally conscious consumers.

Another strategy for promoting sustainability in flour milling is through the optimization of production processes to minimize waste generation. By improving milling efficiency and reducing losses during processing, companies can decrease the amount of waste produced and increase overall resource utilization. This can be achieved through investments in new technologies, training for staff, and continuous improvement initiatives to identify and address areas of inefficiency.

Furthermore, implementing sustainable packaging practices can also contribute to reducing waste in flour milling. By using recyclable or compostable materials for packaging, companies can minimize the environmental impact of their products and appeal to environmentally conscious consumers. Additionally, investing in packaging designs that prolong the shelf life of flour products can help reduce food waste and improve overall sustainability.

Overall, flour milling plays a crucial role in the food industry, and by adopting zero waste initiatives, companies can promote sustainability and reduce their environmental footprint. Through the development of new products using milling byproducts, optimization of production processes, and implementation of sustainable packaging practices, flour milling companies can minimize waste generation and contribute to a more sustainable food system.

FAQs:

Q: What are some common byproducts generated during flour milling?

A: Common byproducts include bran, germ, and shorts, which are often used as animal feed but can also be repurposed for human consumption or other applications.

Q: How can companies reduce waste in flour milling?

A: Companies can reduce waste by developing new products using milling byproducts, optimizing production processes, and implementing sustainable packaging practices.

Q: What are the benefits of implementing zero waste initiatives in flour milling?

A: Implementing zero waste initiatives can help companies reduce their environmental footprint, create additional revenue streams, and appeal to environmentally conscious consumers.